CPI offers the inspection services to maintain quality of installations and the components which are used in critical infrastructures. The services includes the certification as a vendor and our testing and quality procedures are in line with global standards. The inspection services will be controlled by our quality team which is capable to perform analytical calculations for complex structures. CPI obtained various customer approvals through stringent audits and product qualifications, testing and complete compliance to the customer specification.

Inspection

Check the pipes and fittings to be installed, in particular for any signs of impact damage, crack or crush. Any end pipe/fittings observed without end caps or any exposed threaded surface shall not be used directly without approval of CPI FSE.

After removing the protection, clean the thread with a low grade wire brush;

Control validity date of JET-LUBE Sealant agent.

Preparation of the Socket & Spigot

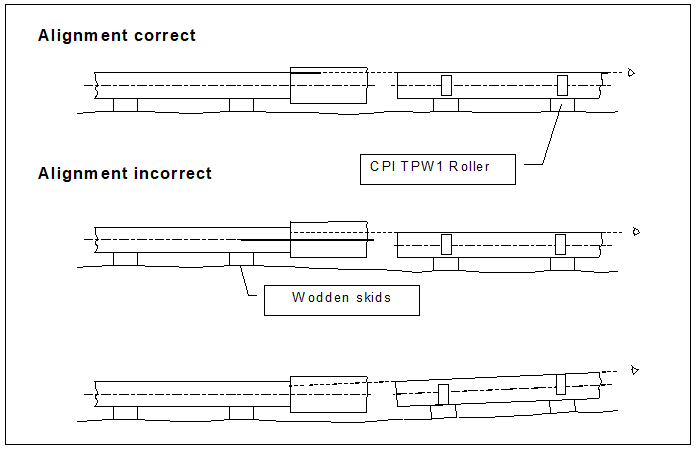

- Pipe and fittings connections shall be aligned as true as possible. Any visually detectable misalignment is not permitted. The alignment can be achieved horizontally as well as vertically by matching the centerlines of either pipe-to pipe or pipe-to fittings as indicated in following sketch.

- Push the spigot in bell carefully in order to have a free rotation on the thread.

- Tight the pipe by hand since spigot is rotating freely.

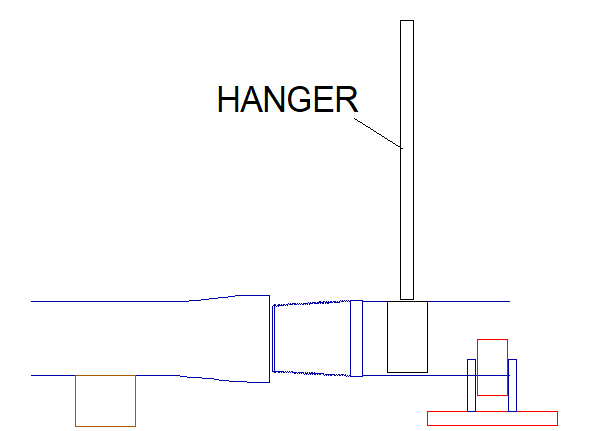

- When tightening by hand is no more possible use a strap wrench hanger since torque is regular.

- Place the hanger as much as possible close to spigot.

- After hand tightening: the spigot position should show a remaining outside gap of 2.5 up to 4 threads. This can be controlled according to neck position of spigot.

- Spigot Thread must be inside the socket after full tightening.

- Clean excessive sealant with soft rag.

- Note that the assembly with sealant shall be executed immediately after spread to avoid entering foreign particles in joint.

Assembly Control

After hand tightening: the spigot position should show a remaining outside gap of 2,5 up to 4 threads. This can be controlled according to neck position of spigot. It must be outside of bell after hand tightening.

After end torque tightening: the remaining outside thread must be less than 2 threads. This can be controlled according to neck position of spigot. It must be inside of bell after full torque tightening.